Fire hose reels are located at strategic places in buildings to provide a reasonably accessible and controlled supply of water for fire extinguishing.

Fire hose reel systems consist of pumps, pipes, water supply and hose reels located strategically in a building, ensuring proper coverage of water to combat a fire.

The system is manually or automatically operated and activated by opening a valve or pulling the hose enabling the water to flow into the hose that is typically 30 meters away. The system pressure loss will activate the pump ensuring adequate water flow and pressure to provide a water jet of typically a minimum of 10 meter from the nozzle.

Dry Riser – Inlet Breechings, Gate Valves, Hydrant Valves, Pressure Regulating Valves, Air Release Valves and Cabinets

A Dry Riser or Standpipe System is an arrangement of piping, valves, hose outlets, and allied equipment with outlets located in such a manner that water can be discharged through hose and nozzles attached to such outlets, for the purpose of extinguishing a fire. These systems include:

- Class I-For use by fire departments and those trained in handling heavy fire streams (2 ½ inch or larger hose).

- Class II-For use primarily by the building occupants until the arrival of the fire Department (1 ½ inch hose).

- Class III-For use by either fire departments and those trained in handling heavy hose streams (2 ½ inch or larger hose) or by the building occupants (1 ½ inch or larger hose).

- Combined System-For use where the water piping serves both 2 ½ inch or larger outlets for fire department use and outlets for automatic sprinklers.

The pipe is maintained empty of water. The Dry riser or “Dry Standpipe” is the opposite of a “Wet riser” or “Wet Standpipe” system where the pipes are kept full of water for manual or automatic firefighting operations.

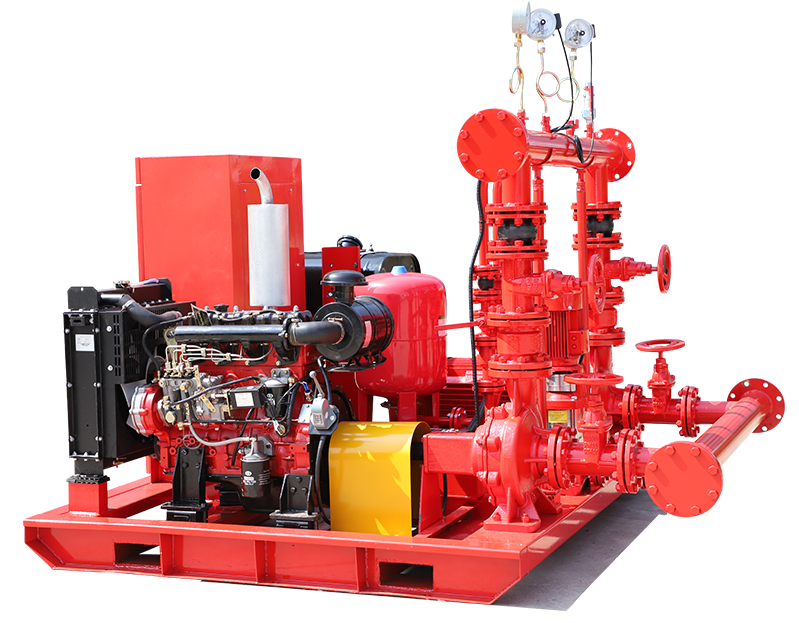

Wet Riser Systems are installed in buildings up to and above 50m subject to the system being designed to provide adequate flow and pressure at the upper floors while dry risers are buildings below 50m. Wet Riser Systems reuire a Fire Pumpset to sustained the waater in the standpipe for automatic operation.

Dry risers have to have adequate fire engine access within 18 m of the dry riser inlet box. Systems in occupied buildings have to be within a fire resistant shaft, usually one of a building’s fire escape staircase enclosures. Most commonly found in High Rise buildings, a Dry Riser system has a number of key components, all of which are available through Shiramafirtex.

At ground level is the Inlet Breeching which is located within an Inlet Breeching Cabinet. This is where the Fire & Rescue Services connect their water supply. The pressurised water travels through the external wall of the property to the interior and up through all floors terminating at the top floor.

At each floor a dry riser gate valve (or landing valve) is accessible for internal connection and stored within an outlet cabinet.

At the top of the vertical pipework a dry riser air release valve is fitted to allow the air within the pipework to escape when pressurised water is introduced via the inlet breeching.

Shiramafiretex is a leading supplier of Inlet Breechings, Gate Valves, Hydrant Valves, Pressure Regulating Valves, Air Release Valves and Cabinets in Nigeria. We supply a comprehensive range of Wet and Dry Risers equipment from the global leading manufacturers.

We add value to your operations and handle all phases of Dry & Wet Riser system layout, installation, maintenance, inspections and testing with our services and support.

Fire Pump Set

Pillar Hydrant

Water Monitor